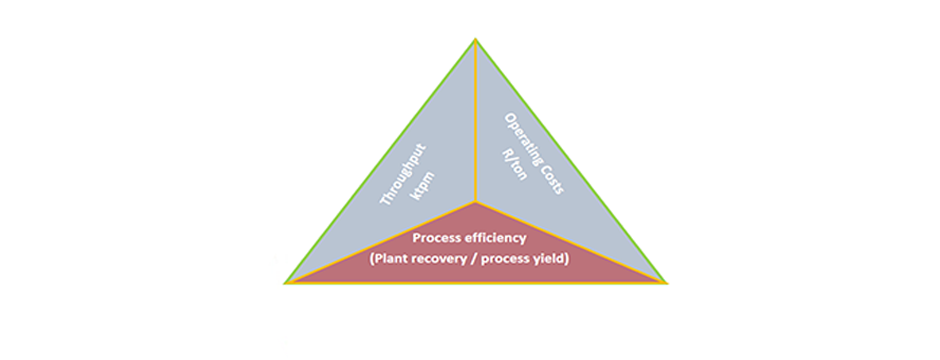

Process Mastery on Optimisation of the TRADE-OFF parameters that influence operational profitability. Here the emphasis is on developing an operating model that is customised to each operation based on historical operational data to deliver the most operational profitability through integration and optimisation of asset sweating initiatives.